Ready Mix Concrete (RMC), or Special Concrete, refers to concrete that is manufactured in a batch plant or factory to a specific composition and then delivered to a job site when it is ready for placement so that it is essentially ready mixed. Making the mix special, adopting what is required for construction is the result given the material quality and expediency of project execution. The RMC eliminates the necessity to station on site as well, saving time as well as sorer labor-intensive tasks.

RMC is becoming popular in construction projects in India apart from small residential buildings to large-scale infrastructure projects such as highways, airports, and skyscrapers. Improving its quality, consistency, and time saving, it is considerably popular.

Key Components of RMC

- Cement: Concrete binding material.

- Aggregates: Fine & coarse (sand, gravel, crushed stone)

- Water: Important for the chemical reaction which bonds cement and aggregates.

- Admixtures: Those chemicals added to increase strength, setting or workability properties.

How is RMC Made?

- Material Selection: The raw materials are high quality according to the project requirements.

- Mixing Process: Making batched materials is shown to work better because the proportional and mixed materials are used in a controlled environment to reach the required consistency and strength.

- Transportation: The moisture content in the mixed concrete is maintained and premature setting is prevented by delivery of the mixed concrete in transit mixers to the construction site.

- On-Site Application: Once delivered, RMC is just poured into the structures the way we want.

Advantages of RMC

1. Consistency in Quality

The mix for RMC must be RMC produced in a controlled environment. It eliminates variability commonly found with onsite mixing.

2. Time-Saving

This also cuts down on waiting for concrete to mix on the job site and construction time becomes shorter.

3. Labor Efficiency

It minimizes on-site labor costs including the need for skilled labor to mix concrete on site.

4. Reduced Wastage

Minimization of wastage of raw materials occurs in the process of percentage one with precise measurements and controlled production.

5. Environmentally Friendly

RMC does make a more sustainable option, with batch production and reduced wastage. Many manufacturers also use recycled materials in their mix, which adds to the eco-friendliness of the product.

6. Enhanced Durability

For better strength and life span, RMC is designed for certain applications.

Types of RMC

1. Standard RMC

Used for residential and commercial projects, a general-purpose mix.

2. High-Strength Concrete

For large-scale projects that fall to the greater load-bearing conducted.

3. Fiber-Reinforced Concrete

Enhanced tensile strength and crack resistance are encoded by contained fibers.

4. Self-Compacting Concrete

It flows easily into tight spaces without the use of mechanical compaction.

Applications of RMC

1. Residential Projects

For house building, apartments, villas.

2. Commercial Buildings

This core model is ideal for use in malls, offices, and high-rise buildings where speed and consistency are so important.

3. Infrastructure Development

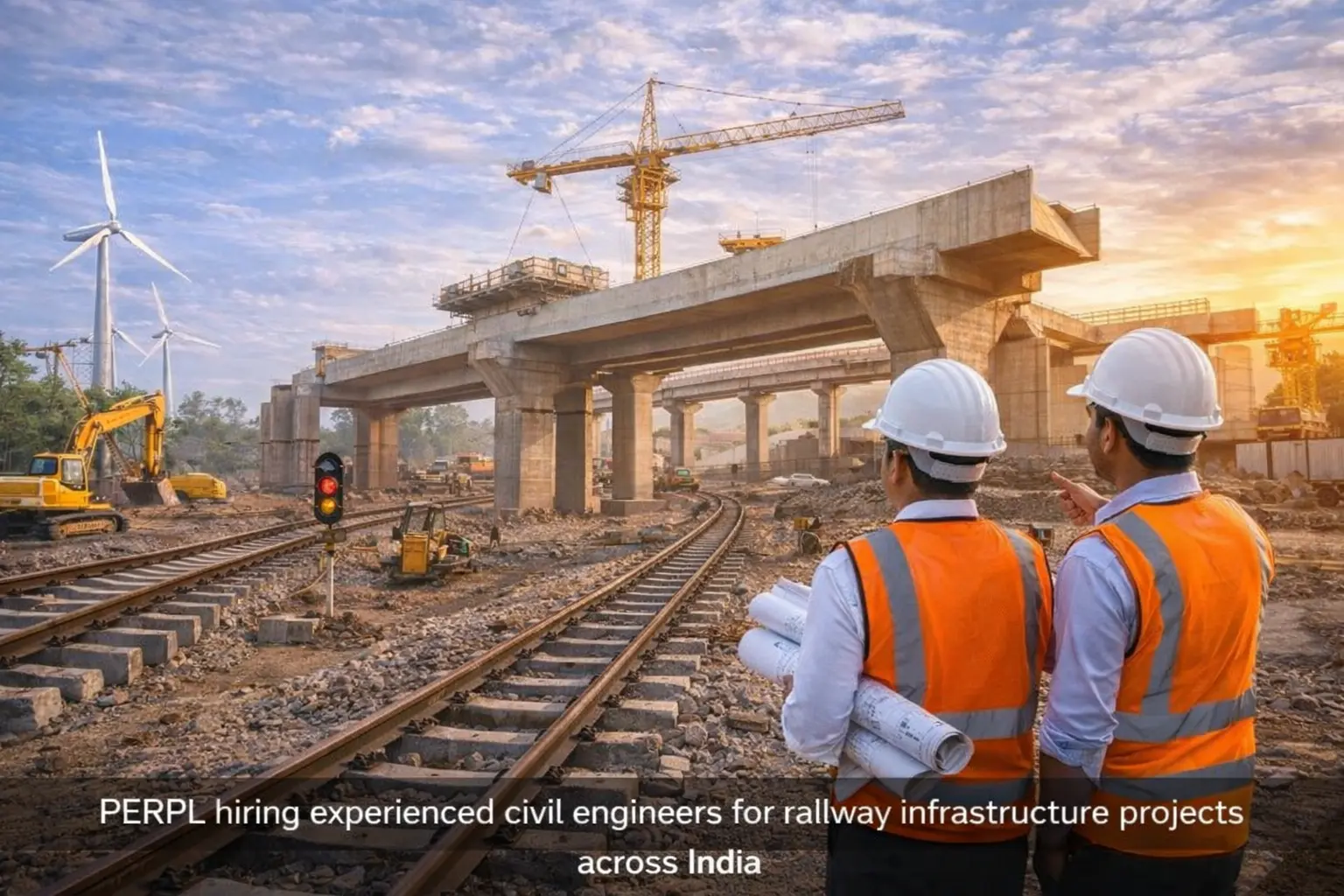

Widely used in highways, bridges, flyovers, and railway projects.

4. Industrial Projects

It gives factories, warehouses, and power plants the durability they need.

5. Urban Landscaping

For constructing parks, pavements, and drainage systems.

Challenges in Using RMC

1. High Initial Cost

Producers typically charge higher than traditional concrete for RMC as a result of its unique production process.

2. Logistics Issues

However, timely delivery is important as delay affects the quality of the concrete.

3. Limited Access

Rural or remote areas can make setting up an RMC plant difficult or arrange delivery difficult.

RMC in the Indian Context

Due to rapid urbanization and development of infrastructure the construction industry in India is witnessing a shift towards Readymix concrete (RMC). Metro cities in India such as Delhi, Mumbai, Bangalore, and Chennai are witnessing the growth of the Indian Ready Mix Concrete market with steady growth.

Reasons for Growing Adoption:

- Greater emphasis on green construction.

- Smart Cities and affordable housing projects as part of government initiative.

- Large scale infrastructure project with stringent quality requirements.

Comparison: RMC vs. Traditional Concrete

| Aspect | RMC | Traditional Concrete |

| Quality | High and consistent | Variable, depending on skill level |

| Time Efficiency | Ready to use | Time-consuming mixing process |

| Cost | Higher initial cost, but cost-efficient | Lower initial cost |

| Environmental Impact | Lower due to reduced wastage | Higher due to material wastage |

| Workforce Need | Reduced | Requires skilled labor |

Future of RMC in India

RMC’s demand will rise with growing urbanization and improved construction technology. Key developments include:

- Automation in RMC Production: Improving accuracy and decreasing the errors of humans.

- Eco-Friendly Innovations: Using recycled materials more.

- Expansion to Rural Areas: Dealing with the issue of remote accessibility.

Innovations in RMC Technology

As the industry of Ready-Mix Concrete (RMC) continues to evolve with the ever-evolving advancements in technology to cater to the increasing construction needs of today. Here are some notable innovations:

1. Smart Batching Plants

Modern batching plants are fitted with IoT-enabled systems that enable real-time monitoring and automated adjustment allowing precise mixing with little human intervention.

2. Green Concrete

Recycled materials and industrial by-products like fly ash and slag are used in RMC variants to reduce the carbon footprint of construction.

3. High-Performance Concrete (HPC)

HPC has been developed for application under extreme conditions which provides enhanced strength, durability, and resistance to environmental influences.

4. Self-Healing Concrete

RMC that cures the cracks of its kind by bacteria or chemical agents is what research into self-healing concrete is leading the way for.

5. Advanced Delivery Systems

Through GPS-enabled transit mixers, transit mixers will enable timely delivery while maintaining the quality of the mix in transit.

Conclusion

Ready Mix Concrete (RMC) is a disruptive solution in the construction industry. RMC is setting new benchmarks in building and infrastructure project execution in terms of time efficiency, eco-friendliness, and value for money because of its superior quality. Though with higher initial costs and logistical hurdles, RMC is facing challenges, the benefits outweigh the drawbacks, and RMC is a must-have in modern construction.

RMC is poised to continue to pick up steam in India, which is only growing and becoming more urban, establishing new standards for construction quality and sustainability.

Read More: What is BIM (Building Information Modeling) in Construction? Benefits & Applications

FAQs What is RMC (Ready-Mix Concrete)? Benefits, Uses, and Innovations

1. What is Ready Mix Concrete (RMC)?

RMC or ready mix concrete is concrete made in a pre-mixed, ready-to-use state, in a factory and it is then delivered to construction sites for use.

2. Why is traditional concrete better than RMC?

Traditional concrete is outdone by RMC because it achieves consistent quality, reduces labor, controls material wastage and saves time.

3. What are the drawbacks of RMC?

RMC is generally hampered by high initial costs and difficulties of logistics in remote areas.

4. Can RMC be used for all types of construction?

RMC is versatile and can suit residential, commercial as well as industrial projects.

5. How much does RMC cost in India?

The rate, however, varies according to the type and place and usually ranges from ₹4,000 to ₹8,000 per cubic meter.