Ultimate Guide to Shore Piles, Secant Piles, and Allied Works : (Covering Capping Beams, Guide Walls, Rock Anchors, and Waler Beams)

Introduction : Ultimate Guide to Shore Piles, Secant Piles and Allied Works

Modern construction often demands deep excavations for basements, metro stations, and high-rise foundations. These excavations must be stabilized to avoid soil collapse, water ingress, and structural failure. To achieve this, engineers rely on a combination of elements such as shore piles, secant piles, guide walls, capping beams, rock anchors, and waler beams.

This ultimate guide explains each component’s role, technical aspects, advantages, disadvantages, and precautions. It is designed for civil engineers, contractors, and students aiming to understand deep excavation systems comprehensively.

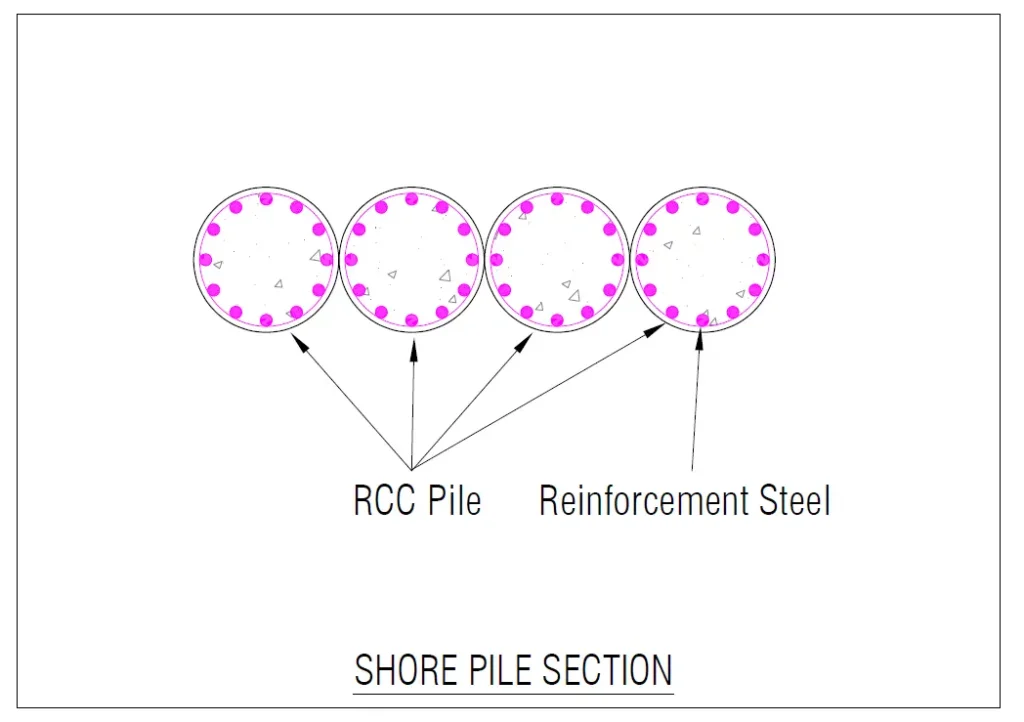

1. What Are Shore Piles?

Shore piles, also called soldier piles, are vertical structural members installed along excavation boundaries to retain soil/ earth. They act as temporary or permanent retaining walls, providing lateral earth support during deep excavations for proposed structures or buildings.

www.civilinfohub.com

1.1 Functions

- Stabilize vertical cuts during excavation.

- Retain soil and prevent collapse of soil.

- Support nearby structures from soil movement.

1.2 Technical Information

- Commonly Reinforced concrete piles and concrete piles.

- Combined with lagging, inclined rock-anchors, or struts for additional stability.

1.3 Advantages and Disadvantages

Advantages:

- Quick to install.

- Cost-effective for temporary works.

- Flexible design for various soil conditions.

Disadvantages:

- Limited water control.

- Requires additional systems for deep excavation.

1.4 Precautions

- Ensure alignment and verticality using guide walls.

- Confirm soil investigation to choose correct pile type.

- Avoid vibrations in sensitive urban zones.

- Provide adequate corrosion protection for steel piles.

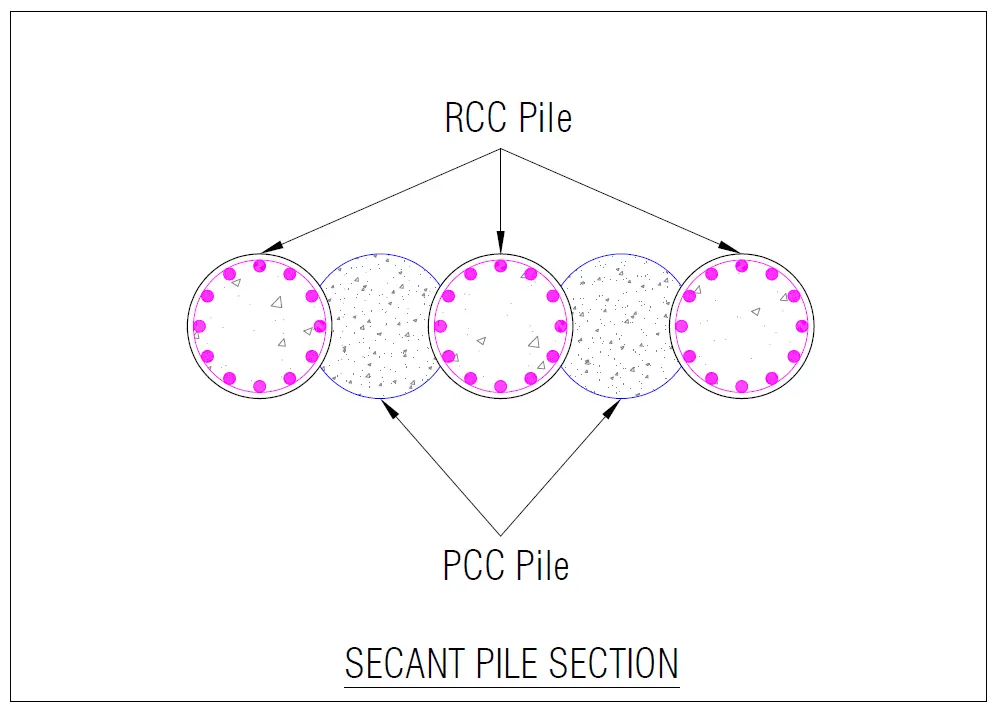

2. What Are Secant Piles?

Secant piles are intersecting bored piles that create a continuous retaining wall. They offer better water tightness and stability than shore piles, making them ideal for deep excavations in dense urban areas.

www.civilinfohub.com

2.1 Functions

- Retain soil and water during excavation.

- Provide structural support for deep basements.

- Reduce ground movement near adjacent buildings / structures.

2.2 Technical Information

- Overlap between piles: 100–150 mm.

- Constructed using rotary piling rigs.

- Types:

- Hard/Hard: Both primary and secondary piles reinforced. (RCC & RCC Piles)

- Hard/Soft: Secondary piles reinforced, primary piles with weaker mix. (RCC & PCC Piles)

2.3 Advantages and Disadvantages

Advantages:

- Stronger and more water-resistant than soldier piles.

- Suitable for tight working spaces.

- Can withstand high lateral pressure.

Disadvantages:

- Higher cost.

- Slower installation compared to shore piles.

2.4 Precautions

- Maintain correct drilling sequence (primary then secondary).

- Use proper concrete mix for water tightness.

- Perform alignment checks before each bore.

- Ensure pile overlap as per design.

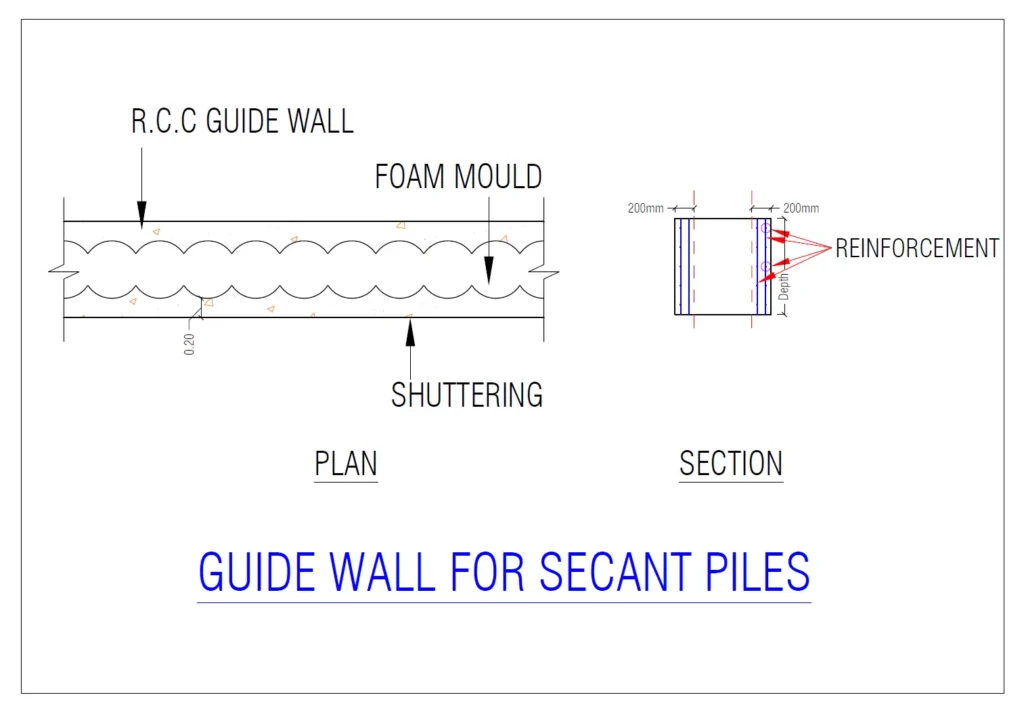

3. Guide Wall – The Alignment Master

Guide walls are short reinforced concrete walls constructed before pile installation. They act as a reference for accurate pile positioning and verticality.

www.civilinfohub.com

3.1 Functions

- Maintains proper alignment of piles.

- Prevents slippage of soil near boreholes.

- Provides support to piling rigs.

3.2 Technical Information

- Typical size: 600–800 mm wide and 1–1.2 m deep.

- Constructed on the excavation boundary before boring.

3.3 Advantages and Disadvantages

✅ Improves accuracy of piling.

❌ Adds cost and time to the project.

Precautions

- Ensure proper curing for durability.

- Check wall level and alignment before boring piles.

- Provide adequate reinforcement to resist soil pressure.

4. Capping Beam – Load Distributor

A capping beam ties all piles together at the top to create a single structural unit. It also acts as a load distributor and platform for superstructure construction.

4.1 Functions

- Transfers superstructure loads to piles evenly.

- Provides lateral restraint to pile heads.

4.2 Technical Information

- Made of reinforced concrete.

- Designed per IS 2911 and IS 456 standards.

- Reinforcement anchored into piles with adequate development length.

4.3 Advantages and Disadvantages

✅ Increases structural integrity.

✅ Serves as a working platform.

❌ Requires precise reinforcement detailing and casting sequence.

4.4 Precautions

- Ensure proper reinforcement anchorage.

- Avoid honeycombing by proper compaction.

- Follow correct curing practices.

5. Rock Anchors – Additional Stability

Rock anchors are steel tendons drilled into stable rock strata and grouted to resist uplift and horizontal forces.

5.1 Functions

- Prevent wall overturning in deep excavations.

- Provide tie-back support to secant or soldier pile walls.

5.2 Technical Information

- Typically high-strength steel strands grouted in boreholes.

- Tested for load capacity before acceptance.

5.3 Advantages and Disadvantages

✅ Adds high stability with minimal space requirement.

❌ Expensive and requires skilled labor.

5.4 Precautions

- Perform proof and performance tests for each anchor.

- Ensure complete grout filling for durability.

- Protect tendons from corrosion.

6. Waler Beam & Other Fabrication Works – Horizontal Support

A waler beam is a horizontal member that distributes anchor loads uniformly to the retaining wall.

6.1 Functions

- Provides continuous lateral support.

- Distributes loads from anchors or struts across piles.

6.2 Technical Information

- Made from steel or reinforced concrete.

- Connected to piles using brackets or anchor bolts.

6.3 Advantages and Disadvantages

✅ Improves wall stability.

❌ Requires extra fabrication and maintenance.

6.4 Precautions

- Check alignment and weld quality for steel walers.

- Apply anti-corrosion coatings.

- Inspect connections regularly during excavation.

7. IS Codes & Standards Referenced

- IS 2911 – Design and Construction of Pile Foundations.

- IS 456:2000 – Concrete Design Standards.

- IS 10262 – Concrete Mix Design.

- BS EN 1536 – Execution of Special Geotechnical Works – Bored Piles.

- ACI 543 – Design of Pile Foundations.

8. Common Mistakes to Avoid

- Skipping guide walls, leading to pile misalignment.

- Insufficient overlap in secant piles, causing water leakage.

- Improper tensioning of rock anchors, reducing stability.

- Neglecting waler beam fabrication quality.

- Poor curing of capping beams, leading to cracks.

9. FAQs

Q1: Which is better – secant piles or diaphragm walls?

Secant piles are preferred in restricted urban sites as they require less space and provide good water tightness.

Q2: Why do we need a capping beam?

It connects piles to form a continuous system and ensures even load transfer to the foundation.

Q3: What is the purpose of a waler beam?

To distribute anchor loads uniformly and maintain stability of retaining walls.

10. Conclusion

Deep excavation support systems require precise design and execution. Elements like shore piles, secant piles, guide walls, capping beams, rock anchors, and waler beams work together to ensure safety and structural stability. Shore Piles Secant Piles are main key elements in the construction activities where soil is poor in conditions.

Always follow IS codes and structural design principles for long-term durability and safety.

11. Disclaimer

This post is for informational purposes only. Always refer to relevant IS codes and consult a qualified structural engineer before executing any design or construction work.

Read More :

https://civilinfohub.com/top-piling-contractors-in-mumbai-india/

https://civilinfohub.com/waterproofing-techniques-for-buildings/

2 thoughts on “Ultimate Guide to Shore Piles Secant Piles and Allied Works : 2025”