Discover what Top-Down Construction is, how it works, and why it’s transforming the way deep basements and high-rise buildings are built. Learn about its advantages, disadvantages, and practical applications in modern civil engineering.

Introduction

In today’s fast-paced urban world, where land is scarce and construction timelines are tight, engineers are constantly seeking innovative building methods. One such groundbreaking technique is the Top-Down Construction Method — a process that allows simultaneous construction of superstructure and substructure, saving valuable time and minimizing site disruptions.

Unlike traditional bottom-up construction, where the foundation and basements are completed before starting the superstructure, top-down construction works in reverse — or rather, in both directions at once.

Let’s explore how this method works, its benefits, challenges, and real-world applications.

🏗️ What Is Top-Down Construction?

Top-down construction is a method where the above-ground (superstructure) and below-ground (substructure) parts of a building are constructed at the same time.

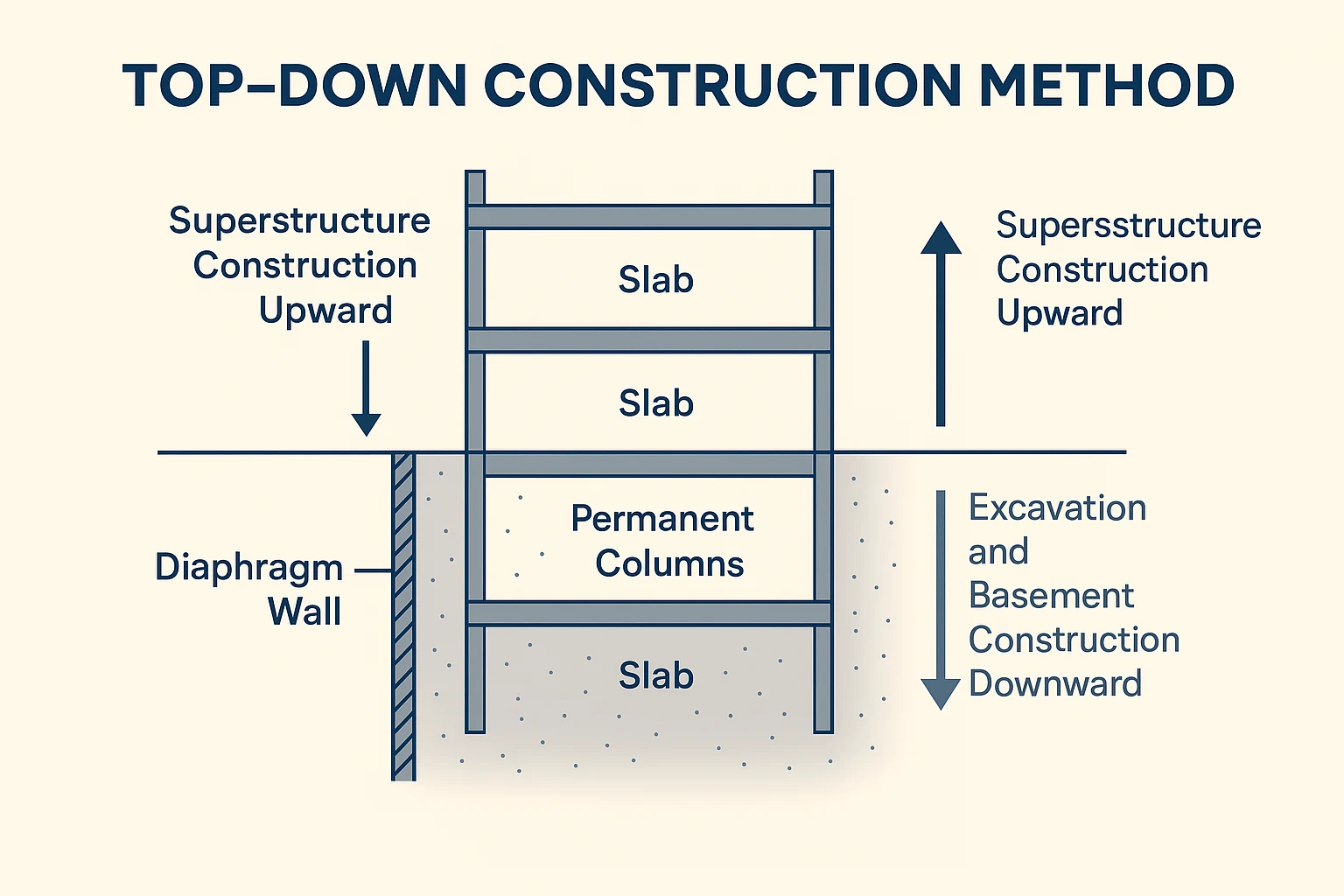

In this technique, the ground floor slab is cast first, supported by permanent columns that extend deep into the ground. Excavation then continues below this slab, floor by floor, as the basement levels are built downward — while the superstructure simultaneously rises upward.

It’s a highly efficient method commonly used for high-rise buildings, underground parking structures, and metro stations, especially in congested urban areas.

⚙️ Step-by-Step Process of Top-Down Construction

Here’s a detailed sequence of how this system is typically executed:

1️⃣ Construct Diaphragm Walls or Retaining Walls

Before starting, reinforced diaphragm walls or secant pile walls are constructed around the site to retain soil and control groundwater.

These walls serve both as permanent basement walls and earth-retaining structures during excavation.

2️⃣ Install Guide Walls and Permanent Columns

Steel or concrete permanent columns are installed through openings where the future basement will be located. These columns are anchored to the base of the diaphragm wall and extend up to the superstructure level.

3️⃣ Cast the Ground Floor Slab

The ground floor slab is constructed next. It acts as a working platform for above-ground activities and provides horizontal support to the diaphragm walls.

4️⃣ Excavate Below the Ground Floor Slab

Excavation continues beneath the ground floor slab through temporary openings left during casting. Excavated material is lifted to the surface using cranes or conveyors.

5️⃣ Construct Basement Floors Downward

After each level is excavated, the corresponding basement slab and walls are cast. This process is repeated until the lowest basement level is completed.

6️⃣ Simultaneously Build Superstructure Upward

While basement work progresses downward, the superstructure (columns, slabs, and beams) rises upward — optimizing construction time.

🏙️ Illustration: Top-Down Construction Process

Alt text: Step-by-step illustration showing simultaneous upward and downward construction with diaphragm wall, slabs, and excavation process.

⚖️ Comparison: Top-Down vs Bottom-Up Construction

| Feature | Top-Down Construction | Bottom-Up Construction |

|---|---|---|

| Sequence | Superstructure and substructure built simultaneously | Substructure first, then superstructure |

| Time Efficiency | High — concurrent work saves time | Slower due to sequential work |

| Excavation Support | Diaphragm walls act as permanent supports | Temporary shoring often required |

| Cost | Higher initial setup cost | Relatively lower initial cost |

| Space Requirement | Ideal for tight urban sites | Requires more open working space |

| Ground Movement | Minimal due to slab bracing | Greater due to open excavation |

💡 Advantages of Top-Down Construction

✅ Time Savings:

Both above and below-ground works proceed together, significantly reducing the overall project duration.

✅ Reduced Ground Movement:

Ground slabs act as braces to the diaphragm walls, minimizing lateral soil movement.

✅ Improved Safety:

Since excavation is covered by slabs, it’s safer for workers and nearby structures.

✅ Early Superstructure Start:

Superstructure can begin almost immediately after the ground floor slab is cast.

✅ Minimal Environmental Impact:

Reduces dust, noise, and disturbance to surrounding areas.

✅ Effective Groundwater Control:

Diaphragm walls prevent water ingress during deep excavation.

⚠️ Limitations and Challenges

🔸 Complex Coordination:

Requires advanced planning between structural, geotechnical, and construction teams.

🔸 Restricted Access:

Excavation under slabs limits space for machinery and material handling.

🔸 Difficult Waterproofing:

Ensuring water tightness at construction joints is technically demanding.

🔸 High Initial Cost:

Specialized equipment, diaphragm walls, and technical expertise increase initial expenses.

🔸 Skilled Execution Needed:

Only experienced contractors can manage the precision required in sequencing.

🏢 Real-World Applications

Top-down construction has been successfully implemented in several iconic projects worldwide:

- Burj Khalifa, Dubai – Deep basement construction under limited time constraints.

- One World Trade Center, New York – Simultaneous substructure and tower development.

- Hong Kong MTR Stations – Extensive use for underground metro facilities.

- Mumbai Metro Stations, India – Adopted in dense city areas with space limitations.

🔍 When to Use the Top-Down Method

This method is ideal when:

- Deep basements are required (3+ levels).

- The project site is surrounded by buildings or busy roads.

- There are strict deadlines.

- Groundwater levels are high.

- Urban congestion limits open excavation space.

🧭 Conclusion

The Top-Down Construction Method is a game-changer in civil engineering — offering speed, efficiency, and minimal disruption in urban settings. Though it demands advanced technical expertise and careful planning, the time and space savings make it the preferred choice for modern city projects.

As cities grow vertically and underground space becomes more valuable, top-down construction will continue to define the future of smart and sustainable building development.

📚 Further Reading & References

- Construction Industry Research and Information Association (CIRIA)

- American Concrete Institute (ACI) – Deep Excavation Techniques

- Civil Engineering Portal: Top-Down vs Bottom-Up Construction

Disclaimer

The information provided in this article, “Top-Down Construction Method: Revolutionizing Modern Building Techniques,” is for educational and informational purposes only.

CivilInfoHub.com and its authors strive to ensure the accuracy, reliability, and timeliness of all content published. However, the concepts, construction methods, and practices described herein are based on general industry knowledge and may vary depending on project conditions, local regulations, or engineering judgment.

Readers and practitioners are advised to consult qualified civil engineers, structural consultants, or project management professionals before applying any technique or data mentioned in this article to real-world projects.

CivilInfoHub.com, its team, and contributors shall not be held responsible or liable for any errors, omissions, or outcomes resulting from the use of this information.

All images, diagrams, and illustrations used are for representational and educational purposes only.

If any copyrighted material has been inadvertently used, please contact us for prompt removal or credit attribution.

Frequently Asked Questions (FAQ) – Top-Down Construction Method

1. What is the Top-Down Construction Method?

The Top-Down Construction Method is a technique where the above-ground structure (superstructure) and below-ground levels (basement or substructure) are constructed simultaneously.

In this process, the ground floor slab is built first, and excavation continues beneath it while upper floors rise — saving time and space, especially in urban areas.

2. What is the difference between Top-Down and Bottom-Up Construction?

In Bottom-Up Construction, the entire foundation and basement are completed before the superstructure begins.

In Top-Down Construction, both are built together — the superstructure goes up while basements are excavated and built downward.

This method greatly reduces project duration and ground disturbance.

3. When is the Top-Down Construction Method used?

It is commonly used when:

- The project site is congested or surrounded by other buildings.

- Deep basements (3 or more levels) are required.

- Tight deadlines or limited working space exist.

- Groundwater control or soil stability is a concern.

Examples include metro stations, high-rise buildings, and commercial complexes in urban centers.

4. What are the advantages of Top-Down Construction?

Key benefits include:

✅ Faster completion due to simultaneous construction.

✅ Reduced ground movement and better stability.

✅ Safer and cleaner work environment.

✅ Early start of above-ground works.

✅ Less noise and disruption to surrounding areas.

5. What are the disadvantages or limitations of this method?

Some challenges include:

⚠️ Complex planning and sequencing.

⚠️ Restricted access for excavation under slabs.

⚠️ Higher initial cost.

⚠️ Requires skilled engineers and specialized contractors.

⚠️ Difficult waterproofing at basement levels.

6. What types of structures use the Top-Down Method?

This method is ideal for:

- High-rise towers

- Underground parking facilities

- Metro and subway stations

- Deep basements in commercial or residential projects

7. Is the Top-Down Method more expensive than traditional methods?

Yes, initial costs are typically higher due to the need for diaphragm walls, permanent columns, and advanced coordination.

However, these costs are often offset by shorter project duration, reduced excavation support, and early revenue generation from completed floors.

8. What materials are commonly used in Top-Down Construction?

The main materials include:

- Reinforced Concrete (RCC) for slabs, diaphragm walls, and columns.

- Steel for temporary supports and permanent columns.

- Waterproofing membranes and drainage systems for basements.

9. Is Top-Down Construction safe?

Yes, when properly designed and executed, it’s considered safer than open excavations.

The slabs built at each level act as horizontal struts, stabilizing the retaining walls and reducing risk of soil collapse or deformation.

10. Can Top-Down Construction be used for small projects?

It’s generally not economical for small or shallow projects (1–2 basement levels).

Top-down construction is most effective in large-scale, deep excavation projects or sites with limited space.

11. What are diaphragm walls and why are they important?

A diaphragm wall is a deep, reinforced concrete wall built around the perimeter of a site.

It acts as both a retaining wall during excavation and a permanent basement wall after completion, providing structural stability and groundwater protection.

12. What are some famous examples of Top-Down Construction?

Some well-known projects using this technique include:

- Burj Khalifa, Dubai

- One World Trade Center, New York

- Hong Kong MTR Stations

- Mumbai Metro Stations, India

13. What are the main challenges faced during Top-Down Construction?

Common challenges include:

- Managing excavation under restricted access

- Ensuring waterproofing integrity

- Maintaining vertical alignment of columns

- Synchronizing above- and below-ground construction schedules

14. How does Top-Down Construction save time?

While basement excavation continues downward, superstructure construction progresses upward.

This parallel workflow can reduce total project duration by 20–30% compared to traditional methods.

15. Is the Top-Down Construction Method sustainable?

Yes, it can be considered sustainable because:

- It minimizes soil displacement and noise.

- Reduces open excavation time.

- Allows better control over groundwater and site safety.

However, sustainability depends on efficient material use and construction management.

🧾 Final Note

The Top-Down Construction Method is a modern engineering approach that combines innovation, safety, and efficiency — ideal for today’s urban infrastructure demands.

While it requires advanced planning and expertise, the results are often faster, safer, and more space-efficient than traditional methods.

Read More :

Top BIM Software for Construction Companies in 2025: A Complete Guide

AI Prompts for BOQ & Estimation – Save Hours in Quantity Calculations [Civil Engineers’ Guide]

1 thought on “Top-Down Construction Method: Revolutionizing Modern Building Techniques”